3 CYLINDER WATER PUMP

HISTORY

The 3 Cylinder Yamaha Engine is used in a variety of applications for both Yamaha and Arctic Cat. ALL variations of this engine, whether in a Snowmobile or UTV, AND whether Turbo-Charged or Naturally-Aspirated, have seen some water pump issues in various forms. Impeller Shafts have broken as well as the plastic Impeller itself has become detached from the shaft or broke. The OEM plastic Impeller is molded around the shaft. There are several theories as to the cause and several “solutions” have been tried but as of December 2022 a full proof remedy has not been determined.

THEORIES

Pump cavitation appears to be one of the main causes of this problem or at least accentuates the problem. Cavitation appears to occur when engines are operated at elevated temperatures. Some of this could be caused from low cap pressure ratings as it allows for vaporization of the coolant to occur at lower temperatures. Although to the human ear this engine is extremely smooth running when we look at the RPM with an oscilloscope we see that the crank is accelerating and decelerating at low RPM’s and idle. This 3 Cylinder engine with a combustion event every 240 degrees and a 60 degree gap between these events causes this. This scenario is normal and more pronounced on all engines with few cylinders. This appears to be the cause of the OEM Round Drive Pins becoming flattened and the Drive Gear getting very “sloppy” on the Shaft. When this scenario becomes exaggerated is when the Shaft itself appears to break. This acceleration / deceleration of the crank and the Drive Pin wear is why some feel that the weight / mass of the impeller itself needs to be kept to a minimum - and possibly why Yamaha designed the water pump using a plastic impeller. Although, many engine manufacturers use plastic impellers these days purely for cost as a billet or even a cast metal impeller is not cheap to manufacture.

JULY 2023 UPDATE

SkyTrax 3 cylinder water pump development update:

After a series of engine stand tests monitoring pump discharge pressures at different RPMs, The 4 vane impeller edged out the others with better flow at the lower RPM as well as better flow at the higher RPM. The new shaft design with the keys machined into the shaft is working well with early testing. Currently there is almost 5 hours of flight time on the 4 vane impeller. Lots more testing to go but off to a good start.

I also discovered another variable in the equation of the stock impeller longevity. I noticed on the OEM impeller I just pulled out after about 40 hours had the shaft in mounted in the plastic impeller at a angle. So in another words the shaft is not perpendicular to the impeller plane of rotation. It was off drastically. I then inspected the new ones I had here and they were all off. Not nearly as bad as the one I pulled out but they were definitely off. When I indicate them in the lathe they are .015-.025 TIR. On the face at the outer most diameter of the impeller. Could some stock ones last longer than others because they are closer in tollerance?

FAILURES

There has been both OEM failures and aftermarket parts failures. There has been a few plastic impellers detaching from the shaft but this was more than likely caused from an overheating scenario. These particular failures were on engines with no actual coolant temp monitoring so we really don’t know how hot the engine got before the failure or if the over heating was caused from the impeller becoming detached first.

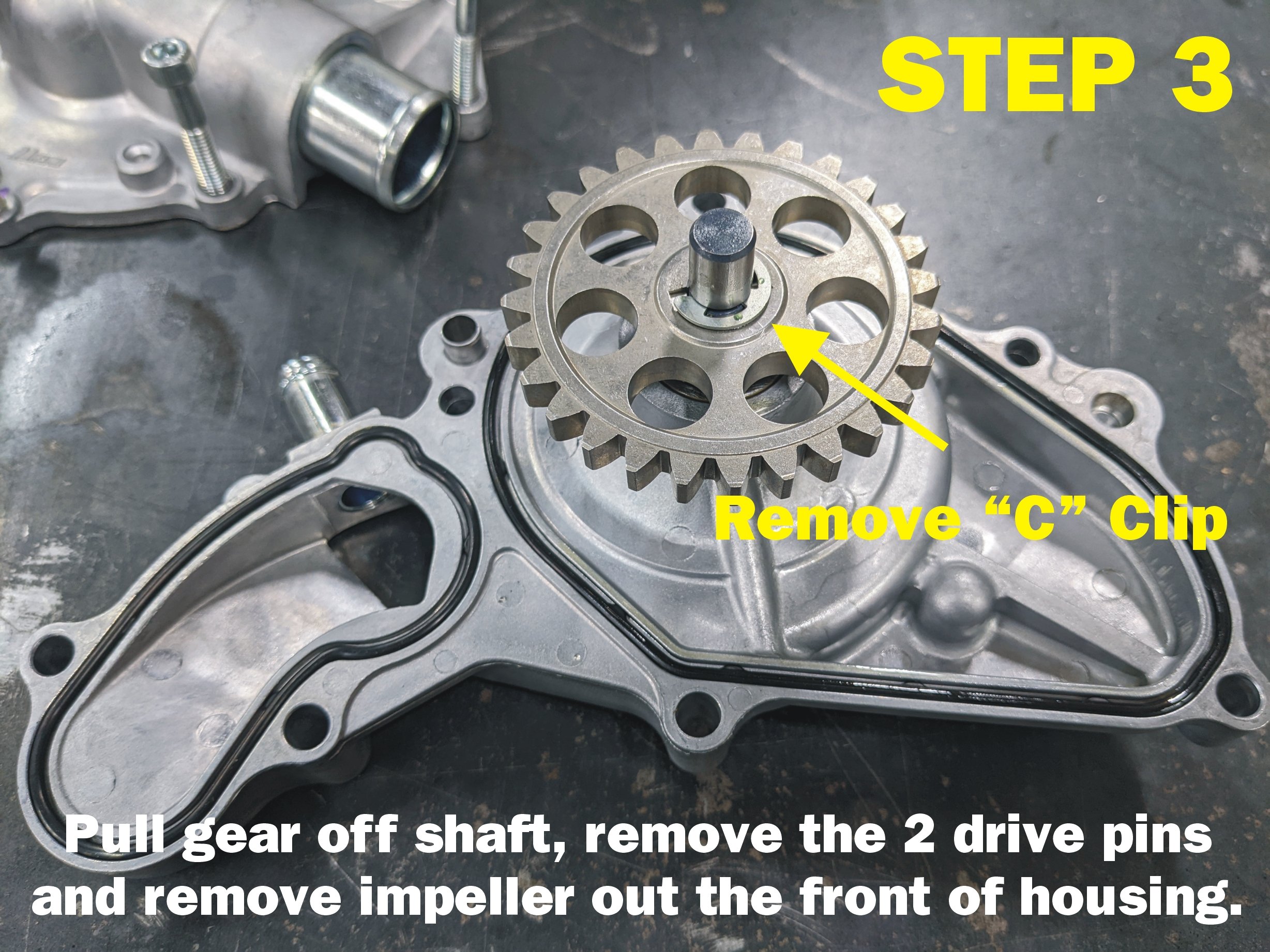

It appears that shaft failures may have been associated with the drive pin holes. Therefore Speed UTV came out with a kit that redesigned the shaft to have the drive pins longitudinally to the shaft. This also required a new custom drive gear. There has since been a failure of this shaft documented.

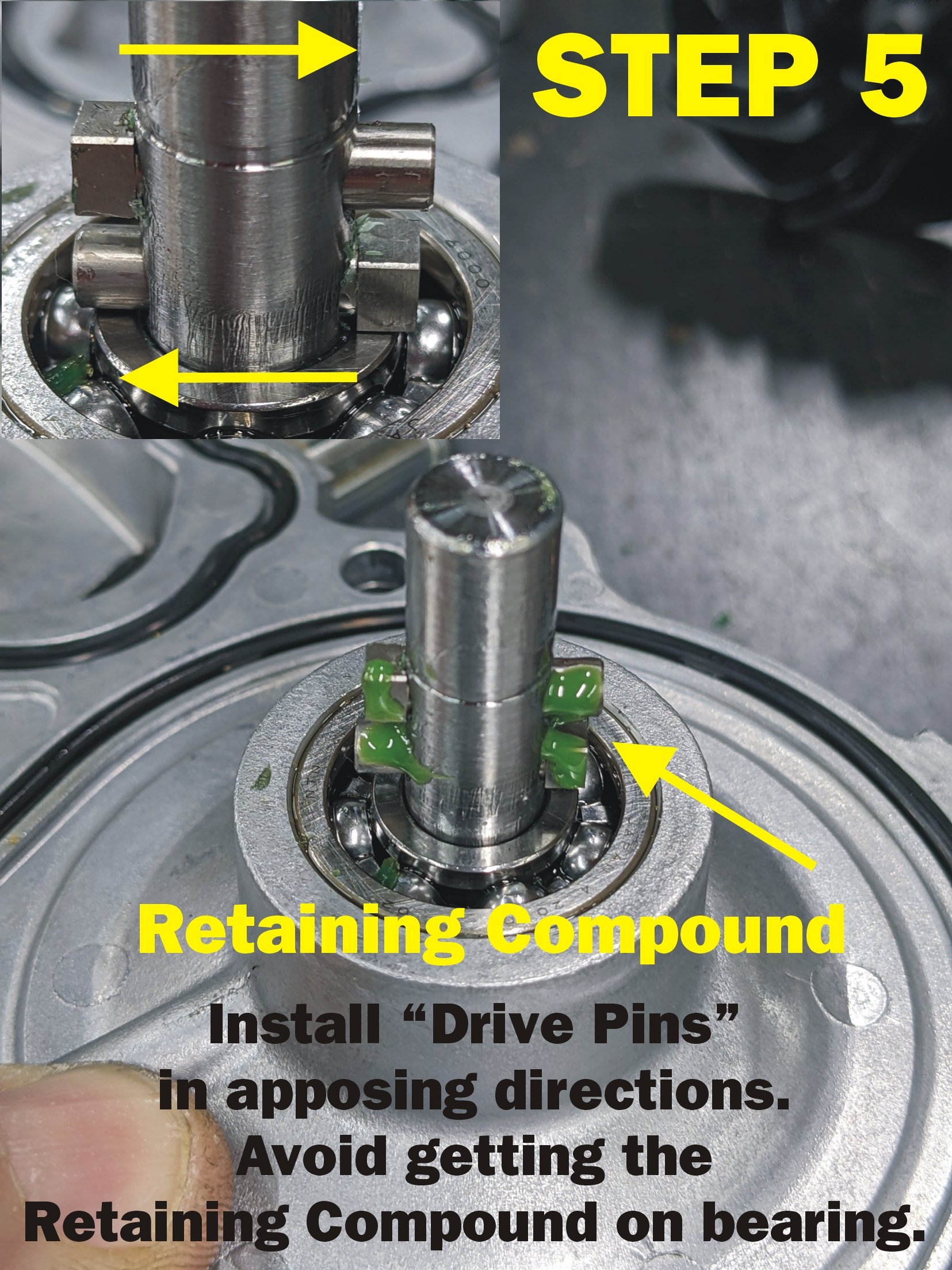

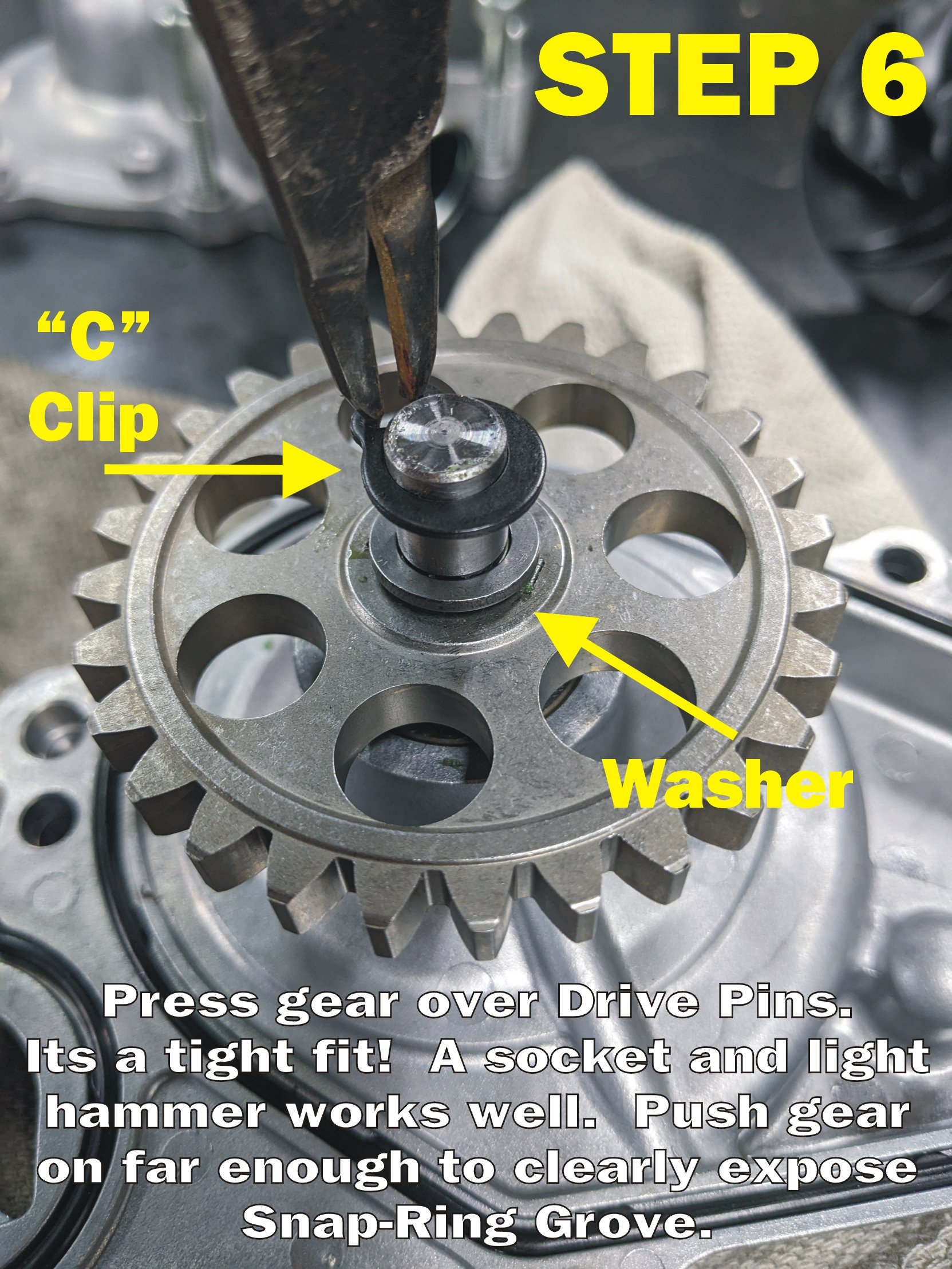

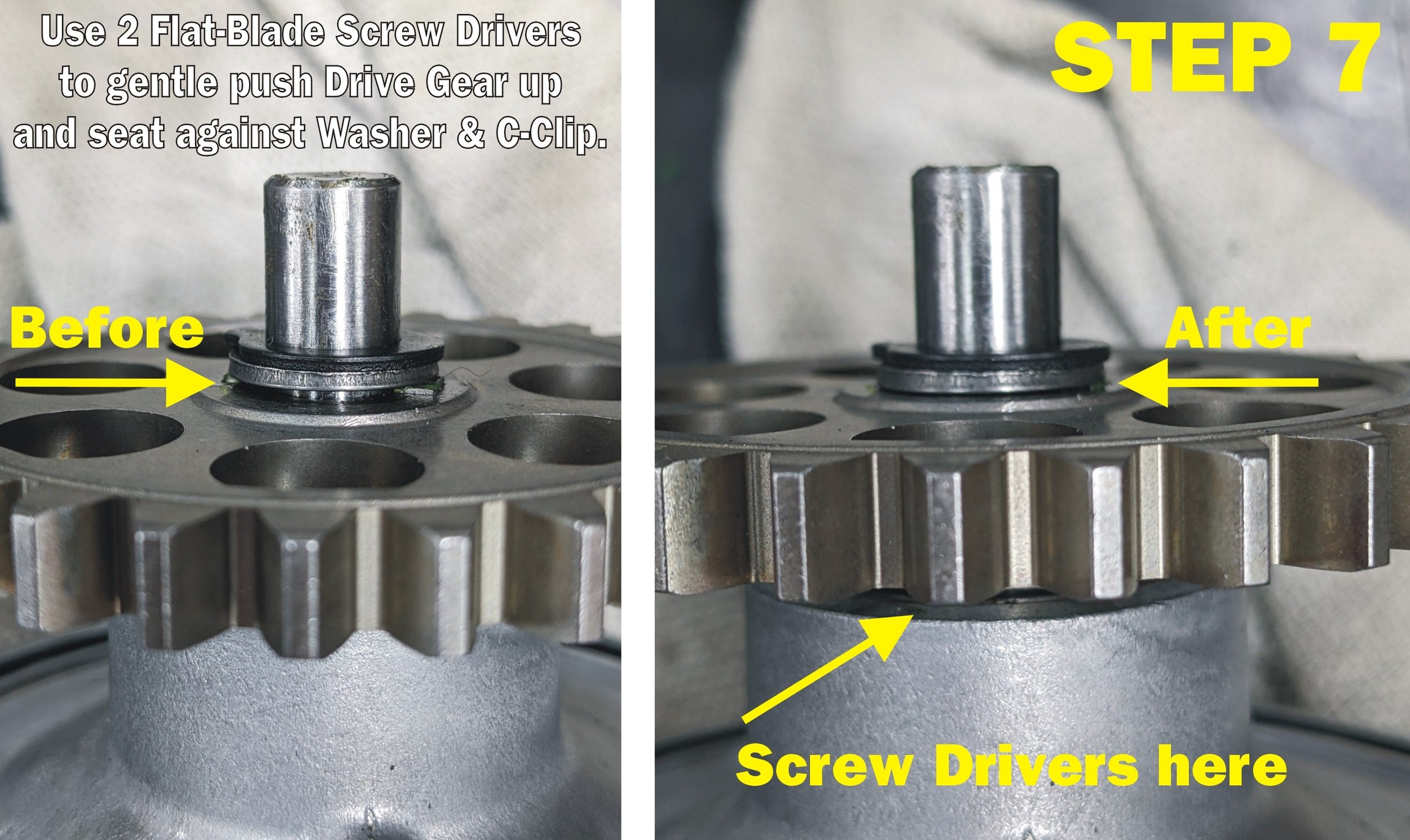

SOLUTION #1 - Replacement Drive Pins

PRECISION SQUARE DRIVE PINS: These at minimum should be installed on any of the 3 Cylinder engines using the OEM shaft & impeller. It’s possible that these pins alone could solve this problem but only time will tell. With these installed the Drive Gear fits very tight with no “slop”. Factory round Drive Pins allow for a reasonable amount of movement even when new. The Square Drive Pins should be installed with retaining compound. The theory is if the Drive Gear never gets sloppy on the shaft the shaft itself will not break. Remember, the acceleration and deceleration of the crank in this engine effects this greatly!

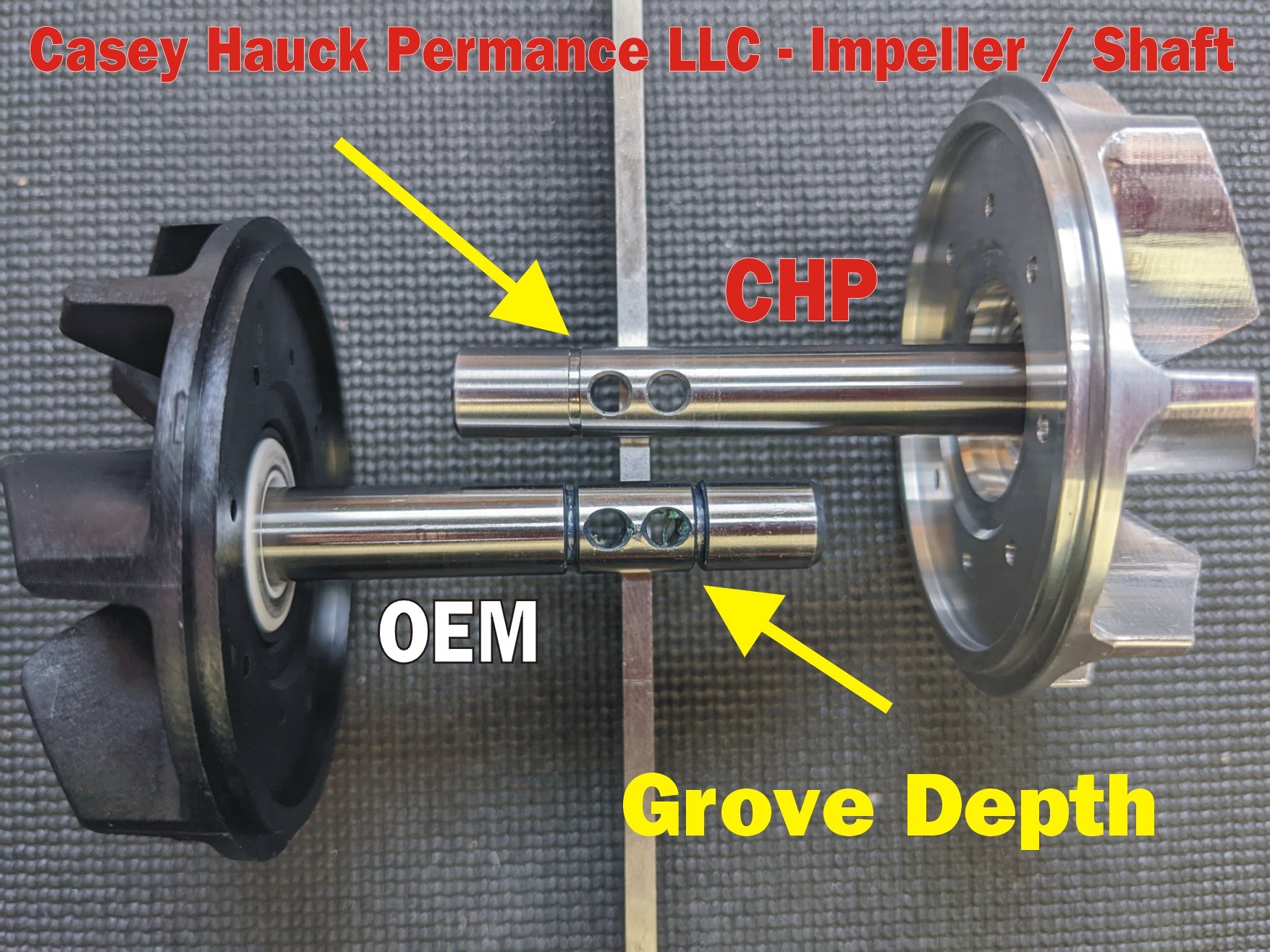

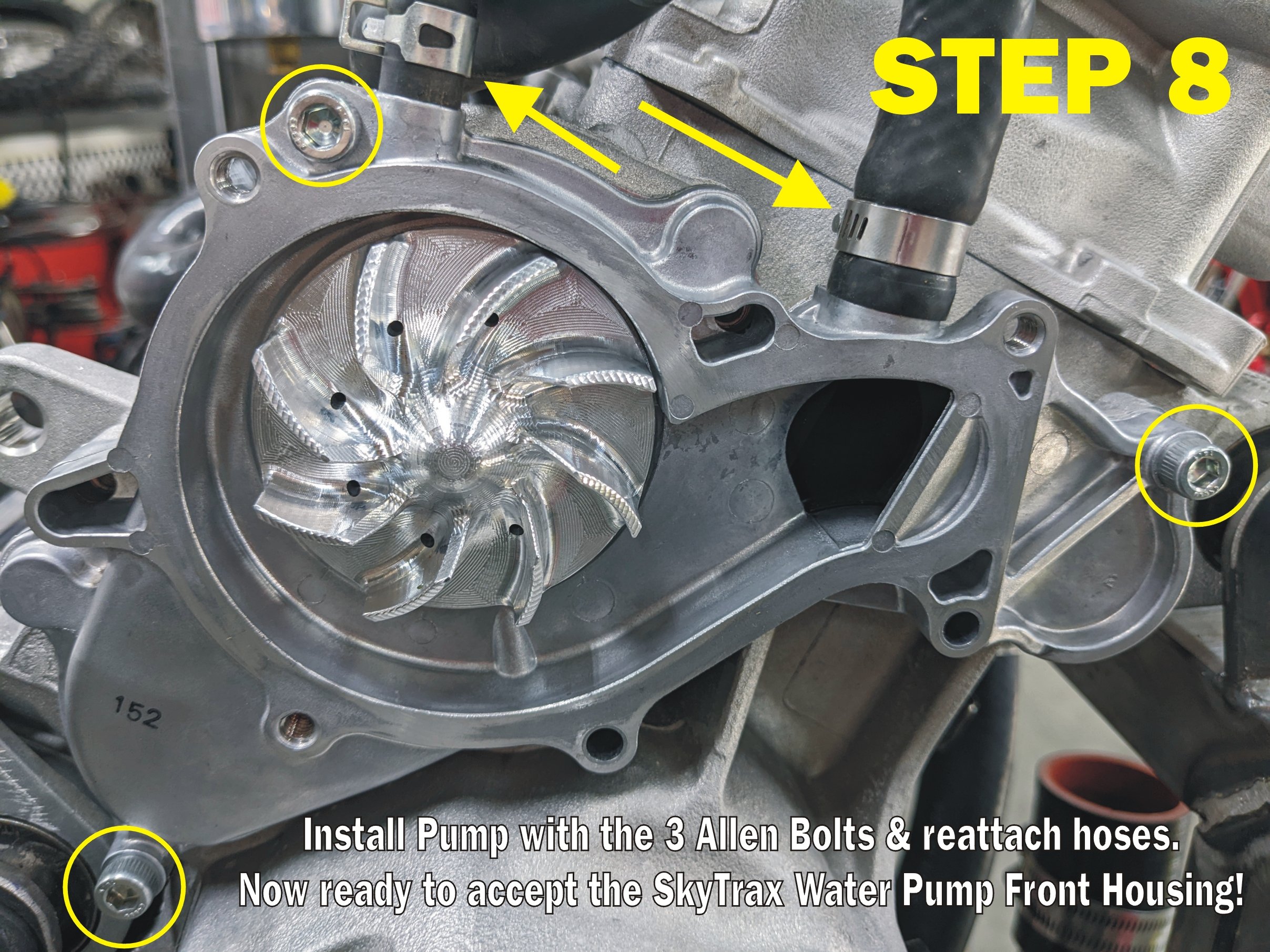

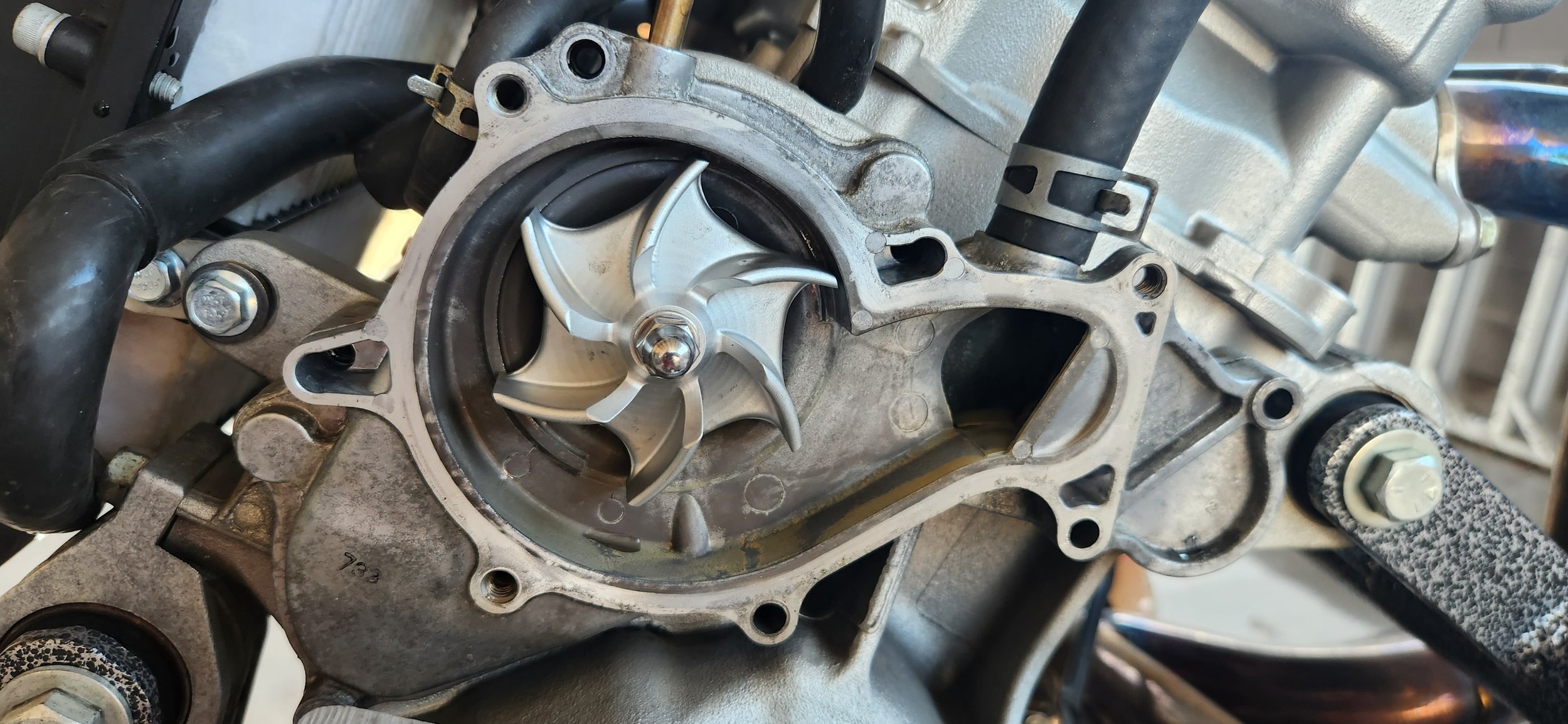

SOLUTION #2 - Billet Impeller, Shaft, & Pins

Casey Hauck Performance LLC is currently offering a replacement Billet Aluminum Impeller along with a redesigned Shaft. The inner “C” Clip Grove has been eliminated and the outer Grove depth has been significantly reduced increasing shaft strength and uses a different type of clip. Along with the Precision Square Drive Pins offered by SkyTrax USA this is our current setup and recommendation going forward.