VIDEO: G-Load Test Fixture.

MOTOR MOUNTS FOR THE

APEX ENGINE

Note - 1: This video is after several cycles, returning to 1G (0 Deflection), and repeating. Motor Mount always returned to 0 Deflection, within a few thousands of an inch!

Note - 2: This was a “Pre Production” mount with Main Tubes being 1” x .047” and all other tubes .5” x .035”. To add an additional factor of safety ALL production Main Tubes have been increased to 1.125” x .058”, and all other tubes increased to .625” x .035. In addition the Engine Mounting Tabs were increased from .070” to .100” and more recently increased to .125”.

Kitfox-4 / 1200 Apex Motor Mount: This is a tight fit, but it can be done. Some aft ballast will often be required for proper CG. The Model 4 above is my personal Kitfox-4 / 1200 and what started the Aviation division of BD Turnkey Engines. First by offering the AEM EFI system for the Apex, and now additional items like the Motor Mounts, Secondary Oil Cooling (coming soon), Header (coming soon), etc in an effort to make this project a more “bolt on” experience for others. HUNDREDS of hours of R & D have went into these designs, re-designs, and modifications. ALL of our components are based on ACTUAL flight testing and results.

6.6 lbs

$2200.00 + Shipping / Handling

All of our motor mounts have been 3D CAD designed and guaranteed to work with our Header (coming soon) and our secondary Oil Cooling / Thermostat Kit (coming soon). ALL tubing material is 4130 Chromoly Steel, LASER Cut & Notched, and Professionally TIG Welded. The design has been G Load Tested to 1.5x (6 G’s) - See Video at top of this page!

Scroll through the pictures of each motor mount below. You can Right Mouse Click pictures to view full size.

Kitfox 5-7 Apex Motor Mount: The Apex fits in this airframe very easily with room to spare honestly. Bryan Bowen has documented the process very well on his Youtube Channel, “Project Kitfox”. We have designed this motor mount to have very desirable CG with no need to add aft ballast. The cowl is currently the biggest challenge in this installation. There are a few options, but starting with the Lycoming Cowl & Firewall will be the easiest.

7.6 lbs

$2200.00 + Shipping / Handling

All of our motor mounts have been 3D CAD designed and guaranteed to work with our Header and our secondary Oil Cooling / Thermostat Kit. ALL tubing material is 4130 Chromoly Steel, LASER Cut & Notched, and Professionally TIG Welded. The design has been G Load Tested to 1.5x (6 G’s) - See Video at top of this page!

Scroll through the pictures of each motor mount below. You can Right Mouse Click pictures to view full size.

The Zenith 701 Apex Motor Mount has been 3D CAD designed to replicate the original specified weight and balance as well as P-Factor Right Offset. This mount uses larger 3/4” 4130 Chromoly support tubes. It also includes the float mounts.

7.7 lbs

CURRENTLY DISCOUNTINUED

All of our motor mounts have been 3D CAD designed and guaranteed to work with our Header and our secondary Oil Cooling / Thermostat Kit. ALL tubing material is 4130 Chromoly Steel, LASER Cut & Notched, and Professionally TIG Welded. The design has been G Load Tested to 1.5x (6 G’s) - See Video at top of this page!

Scroll through the pictures of each motor mount below. You can Right Mouse Click pictures to view full size.

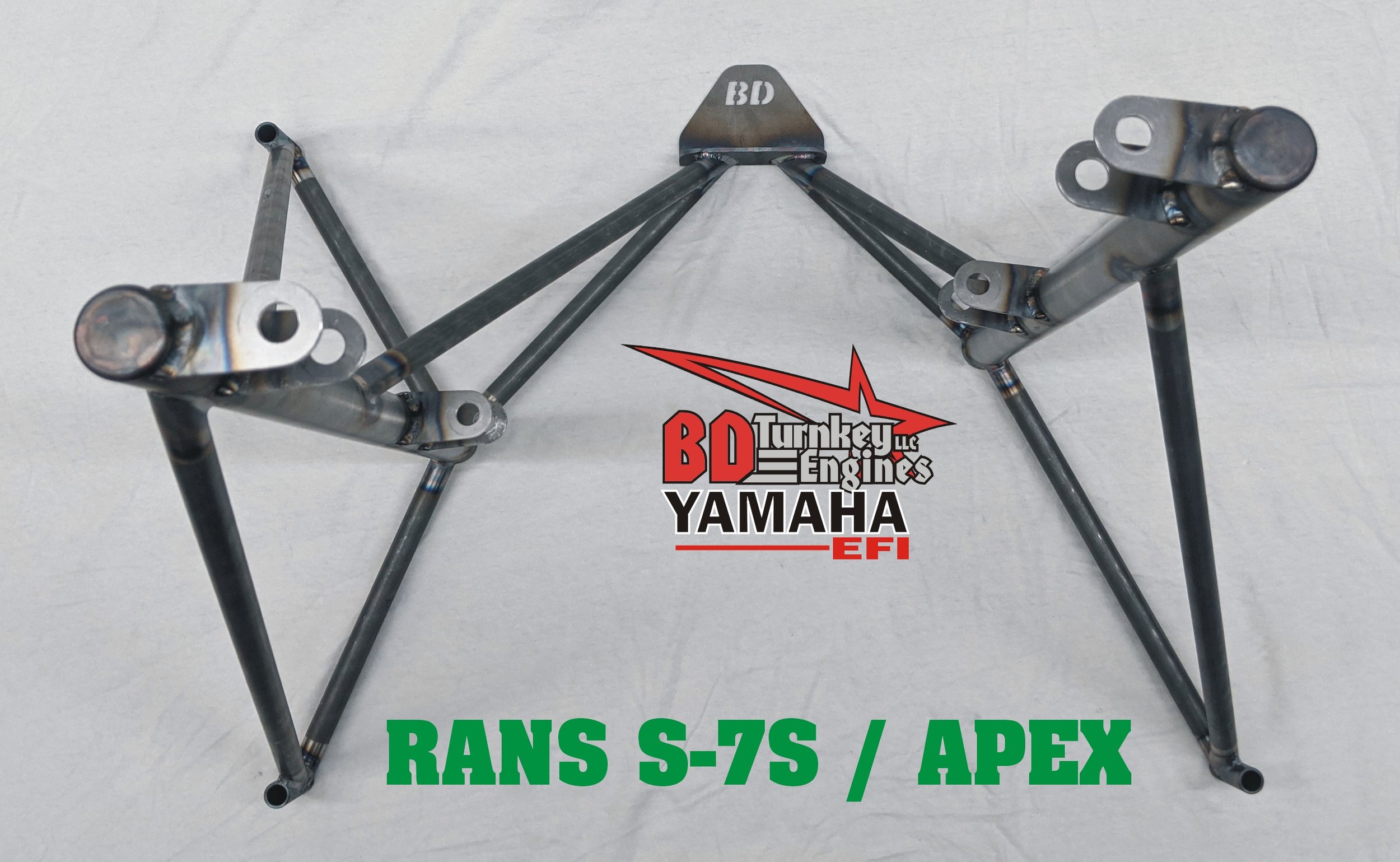

RANS S7 & S7S

CURRENTLY DISCONTINUED

All of our motor mounts have been 3D CAD designed and guaranteed to work with our Header and our secondary Oil Cooling / Thermostat Kit. ALL tubing material is 4130 Chromoly Steel, LASER Cut & Notched, and Professionally TIG Welded. The design has been G Load Tested to 1.5x (6 G’s) - See Video at top of this page!

Just Aircraft - Highlander & Super STOL

Contact Wildwest Aircraft!

Wildwest Aircraft has the exclusive on the Vector motor mounts for these airframes. Click Link to the Right >>>>

Note: Our Vector designed Header does fit this motor mount on these airframes.